Our prefabricated drywall is the fastest and most cost-effective way to get the job done.

Contact us today for a quote.

Our Prefabricated Drywall Profiles are the modern solution for high-quality construction projects.

With over a decade of successful use in Europe, these profiles are now available in North America.

Prefabrication offers numerous benefits including reduced labor costs, improved accuracy and efficiency, reduced waste, and results in much higher quality finishes. As the construction industry shifts towards BIM-based workflows, prefabricated details will become not only a best practice, but a necessity.

Key Benefits

Benefits Of Using Prefabricated Drywall

Increased production and efficiency

Less cutting, cleaning, taping and sanding.

Faster installation

Deliver impressive results in less time.

Cut labour costs

Keep projects on time and on budget.

Perfect 90° corners

With no cornerbead or mud.

Custom made to fit your project

Accurate cutting to within .001”

Self supporting

Self supporting structures.

Explore our

Drywall Profiles

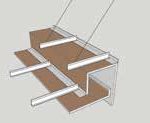

Right Angle Corner

The right angle corner is the plaster cornerbead replacement. A traditionally finished corner takes many steps to complete: 2 cut pieces of drywall, corner bead, 2 coats of plaster minimum, and sanded to finish. By using profiles, the corner is finished once the drywall is installed.

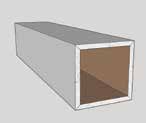

End Caps & Column Boxes

Caps can be used for finishing stub and pony walls, closet openings and ceiling transitions. Our column kits greatly speed up the process of boxing out columns, and can be designed to fit almost any column or specification.

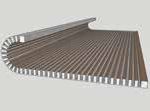

Complex Shapes

Light chases and complicated architectural details are where drywall profiles show their true capabilities, reducing labour and material by a substantial amount.

Flexible Sheet

With a flexible sheet of drywall you can achieve very tight curves without changing material types, resulting in a more seamless transition from straight to curved. The ease of bending the sheet also makes the installation process much more rapid than the traditional method which requires an experienced hand to keep the radius and the face uniform from top to bottom without breaking the material.

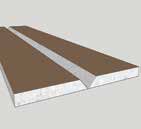

Flat Returns

The single return is used when drywall is butting against another material such as concrete or wood where the angled paper tape cannot be used to close the corner, or for an inset baseboard.

A double return is a much finer finish as it allows for a fully wrapped paper finish front to back. These are used when the back edge is visible. An example would be a reveal edge on a door or finished drywall paneling with a reveal frame.

Solutions

Prefabricated Drywall Applications

Houses

Offices

Commercial Retail

Local business Fit-ups

Airports

Hospitals

Museums

Hotels

Lobby Remodels

Explore

Our Projects

Our prefabricated drywall is a cost effective solution for any job. From new builds to repairs and remodels, our customers are always happy with the results.

Browse through a selection of our finished projects.