Complete Your Drywall Projects In The Fastest And Most Cost-Effective Way With Our Prefabricated Drywall

Ready to save time and money on your next drywall project?

Are you losing money?

The Hidden Costs of Traditional Drywalling

Time Consuming

Crafting perfect corners and handling intricate shapes takes time—and lots of it. Each step, from measuring and cutting to mudding and sanding, adds up quickly, stretching project timelines.

Extra Costs

Traditional drywalling comes with extra costs, as finishing corners, bulkheads, and intricate shapes requires more time, labor, and materials, quickly inflating project expenses.

Imperfect Results

Even with the best materials and expertise, traditional methods leave room for error. Uneven corners or inconsistent shapes can mean costly rework, jeopardizing the polished, professional finish you expect.

Key Benefits

Why Choose Prefabricated Drywall?

Faster installation

Prefab drywall streamlines installation with pre-finished corners and precise dimensions, saving time and keeping your projects on schedule.

Cost Savings

Prefab drywall cuts labor, reduces materials, and minimizes rework, lowering costs without sacrificing quality.

High-Quality Finish

Prefab drywall delivers a flawless finish with pre-finished corners and precise panels, ensuring professional results for any project.

Explore our

Drywall Profiles

Right Angle Corner

The right angle corner is the plaster cornerbead replacement. A traditionally finished corner takes many steps to complete: 2 cut pieces of drywall, corner bead, 2 coats of plaster minimum, and sanded to finish. By using profiles, the corner is finished once the drywall is installed.

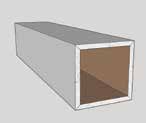

End Caps & Column Boxes

Caps can be used for finishing stub and pony walls, closet openings and ceiling transitions. Our column kits greatly speed up the process of boxing out columns, and can be designed to fit almost any column or specification.

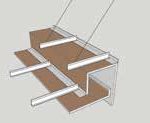

Complex Shapes

Light chases and complicated architectural details are where drywall profiles show their true capabilities, reducing labour and material by a substantial amount.

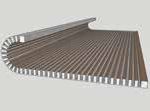

Flexible Sheet

With a flexible sheet of drywall you can achieve very tight curves without changing material types, resulting in a more seamless transition from straight to curved.

The ease of bending the sheet also makes the installation process much more rapid than the traditional method which requires an experienced hand to keep the radius and the face uniform from top to bottom without breaking the material.

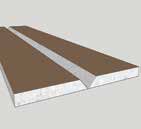

Flat Returns

The single return is used when drywall is butting against another material such as concrete or wood where the angled paper tape cannot be used to close the corner, or for an inset baseboard.

A double return is a much finer finish as it allows for a fully wrapped paper finish front to back. These are used when the back edge is visible. An example would be a reveal edge on a door or finished drywall paneling with a reveal frame.

We are Folded Architectural Finishes

At Folded Architectural Finishes, we bring over 25 years of drywall expertise to every project we support.

Our team understands the constant pressure to deliver on tight deadlines, manage budgets, and maintain high standards.

We’ve faced those challenges ourselves, and that’s why we’re passionate about making the process easier for you.

We’re more than just drywall experts—we’re problem solvers and partners, dedicated to helping you succeed.

Whether you’re tackling multi-unit builds or racing against the clock, you can trust us to provide solutions that streamline your work and elevate your results.

At Folded Architectural Finishes, we’re here to make your vision a reality.

Ready to save time and money on your next drywall project?

Applications

Prefabricated Drywall Applications

Houses

Offices

Commercial Retail

Local business Fit-ups

Airports

Hospitals

Museums

Hotels

Lobby Remodels

How it Works

Your Simple Path to Better Drywall

1. Shop for Your Pieces

Visit our online store to browse a range of pre-made prefab drywall pieces tailored to your needs. Choose the sizes and styles that fit your project.

2. Place Your Order

Checkout is simple and secure. Once you place your order, we’ll prepare your pieces for delivery or pickup.

3. Enjoy the Results

With your prefab drywall pieces in hand, installation becomes quick and hassle-free, leaving you with a professional finish and time to spare. Transform your project with ease!

Frequently Asked Questions

How does prefabricated drywall save me time?

Prefabricated drywall comes ready to install with pre-finished corners and precise measurements. This eliminates the time spent cutting, trimming, and finishing corners, reducing the overall time required for installation. You’ll get the job done faster, which means fewer labor hours and faster project completion.

Isn’t prefabricated drywall more expensive?

While prefabricated drywall may have a higher upfront cost, it ultimately saves you money in the long run. With fewer labor hours needed for installation and less waste from off-cuts, the overall cost of the project is reduced. Plus, the consistent quality means fewer mistakes and rework.

Will prefabricated drywall work for my project?

Our prefab drywall is versatile and can be used for a wide range of projects, including multi-unit residential buildings, commercial spaces, and more. Whether you’re working with standard or custom designs, our team can help you select the right solution for your specific needs.

How do I know the quality of prefabricated drywall is up to standard?

With over 25 years of experience in the drywall industry, we ensure our prefabricated drywall meets the highest quality standards. Our products are designed for durability, consistent performance, and a flawless finish. We’re committed to delivering a product that stands up to the demands of any project.

How do I get started?

Getting started is simple! Just request a quote from us, and we’ll guide you through the process. We’ll provide a detailed estimate based on your project’s requirements and work with you to ensure that everything runs smoothly from start to finish.

What if I run into problems during installation?

Our team is here to support you. If you run into any issues during installation, we’ll provide guidance and solutions to help you get back on track. With decades of experience, we can troubleshoot and offer tips to make your installation as smooth as possible.